Product Collection and Branding

SLIIT

SLIIT is a project-based brand founded by Solomon Choi and Giseok Jang. SLIIT designs branded collections of unique, emotionally engaging products, with a focus on using PLA 3D printing as a core fabrication method. The goal is to create objects that elevate everyday rituals through thoughtful form, tactile interaction, and cohesive storytelling.

FORM FOLLOWS FEELINGS

FORM FOLLOWS FEELINGS

brand design

SLIIT bridges the slit between ordinary and extraordinary moments. The two “ii” in the logo symbolize Solomon and Giseok, co-founders united in design.

-

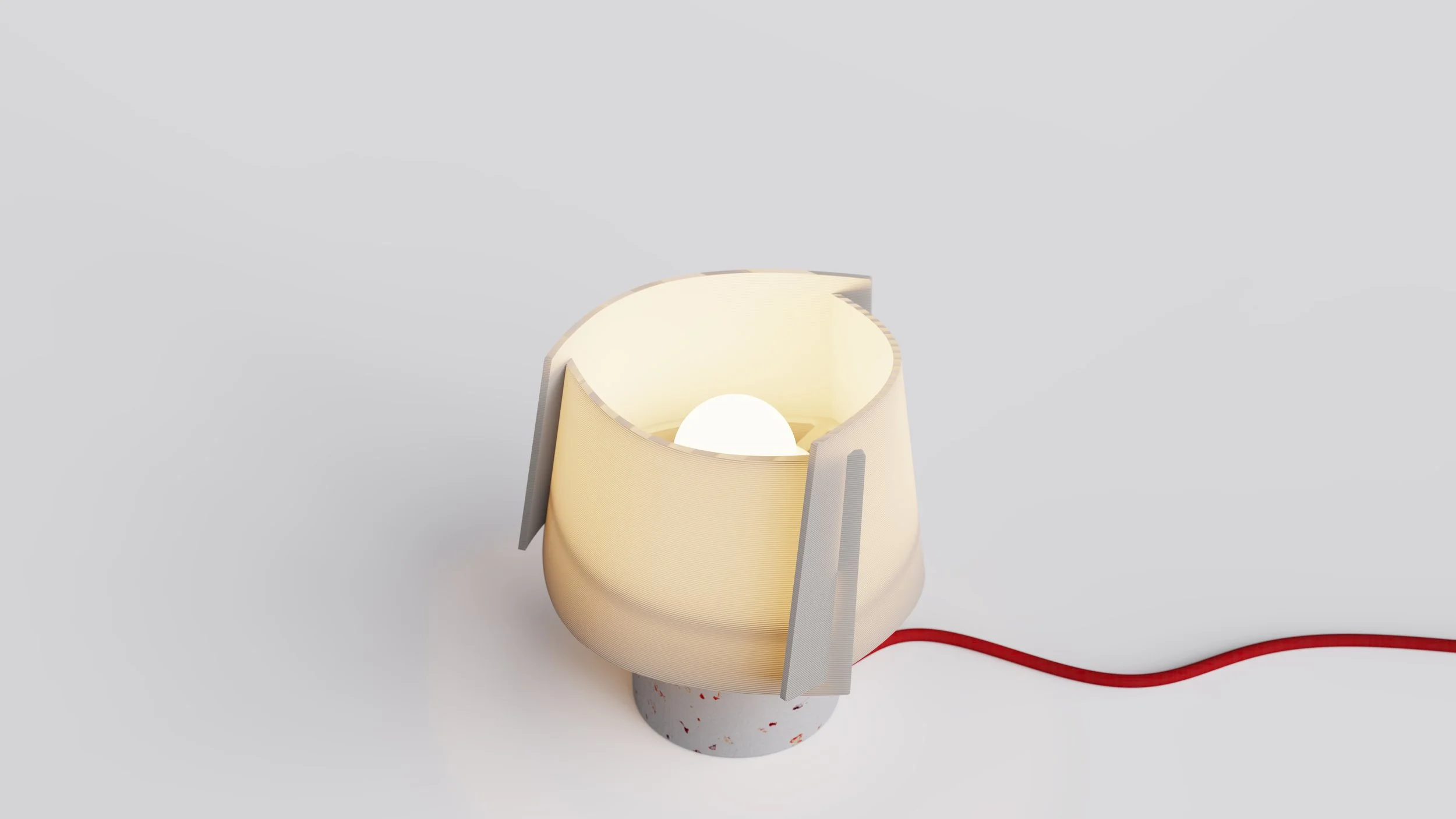

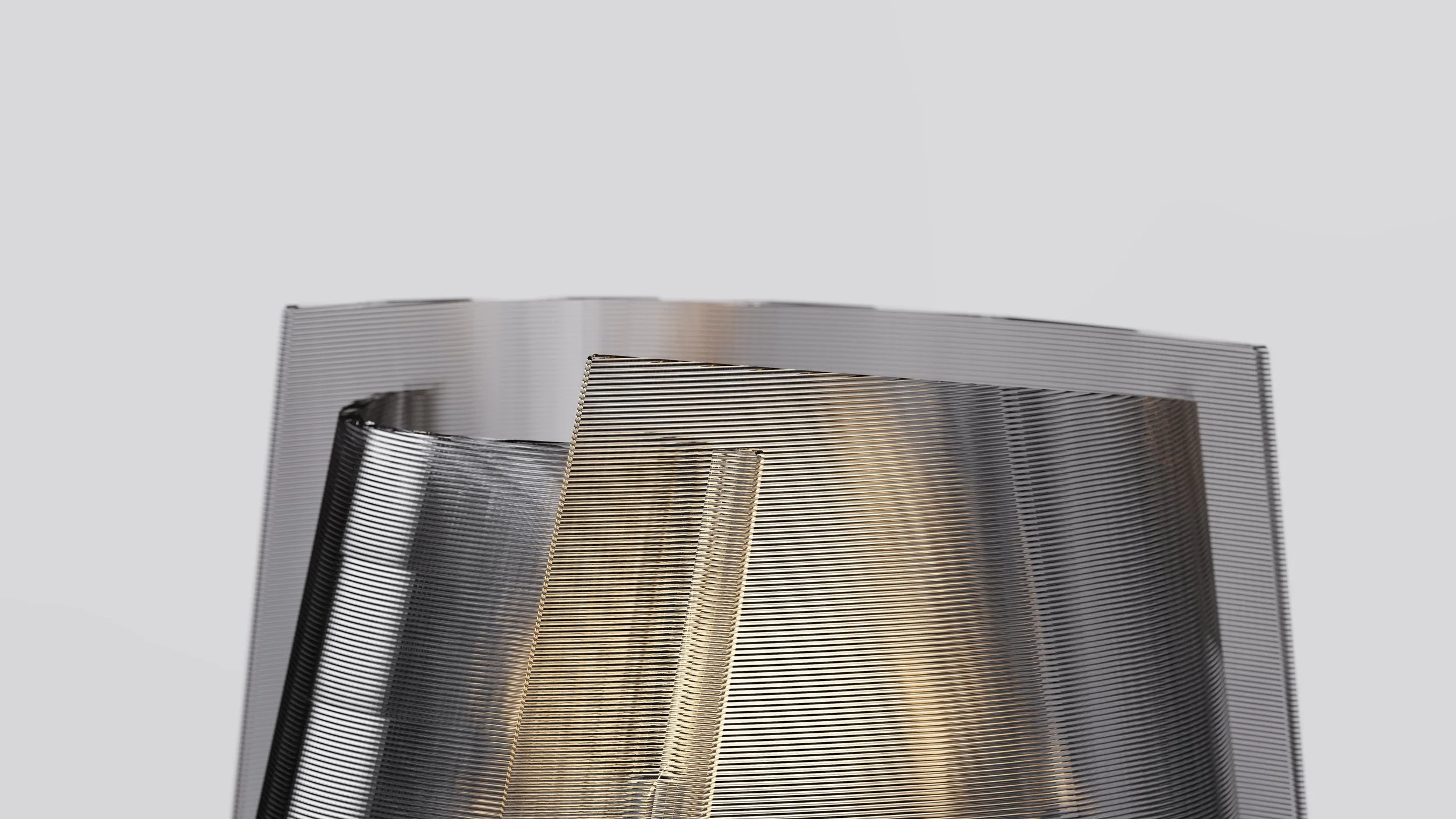

Joon is a table lamp designed to add a subtle accent to a space. It emits soft, diffused light through a 3D-printed lampshade, while textures formed from Jesmonite and recycled plastics create a quietly expressive and sustainable presence.

-

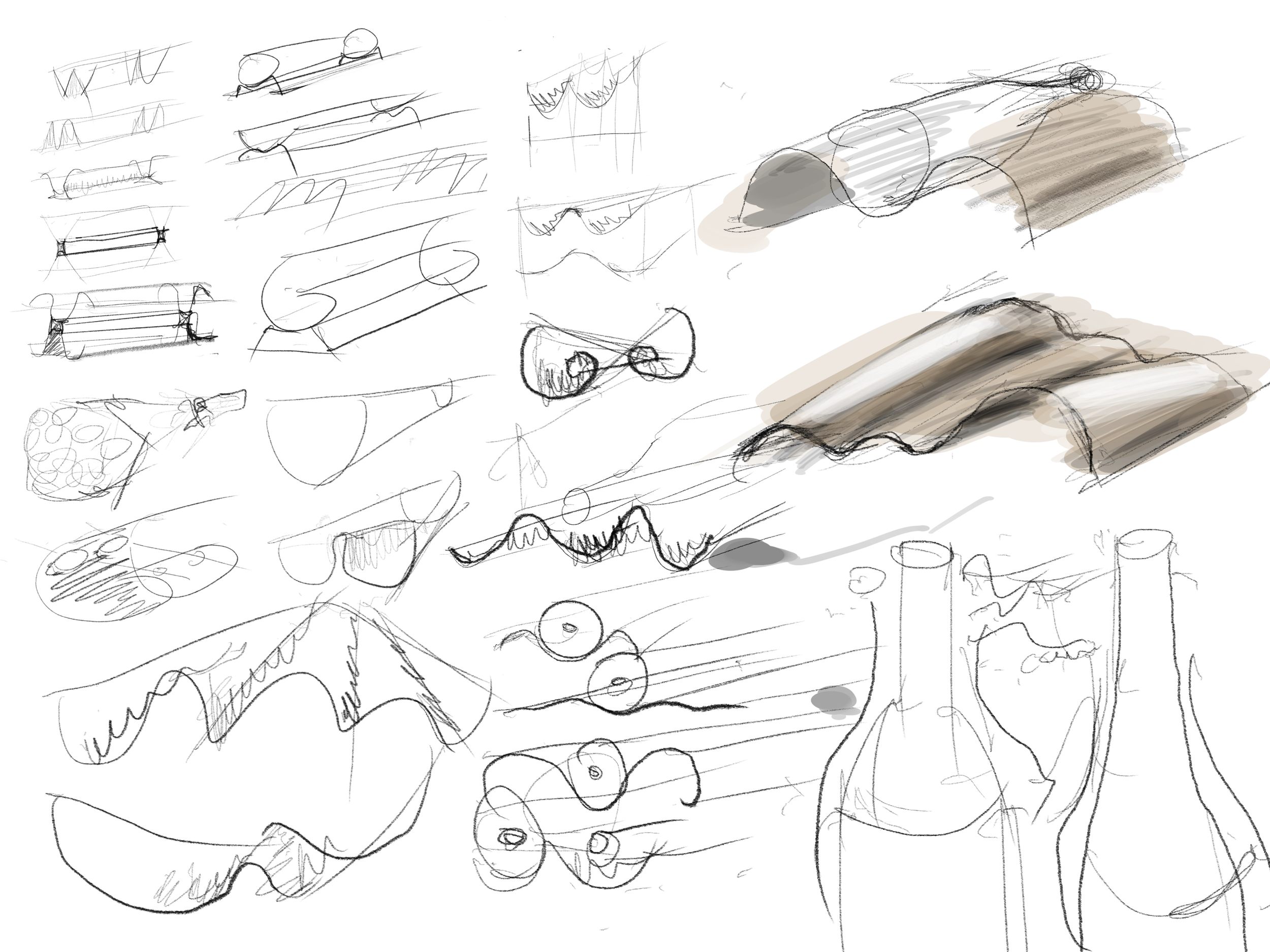

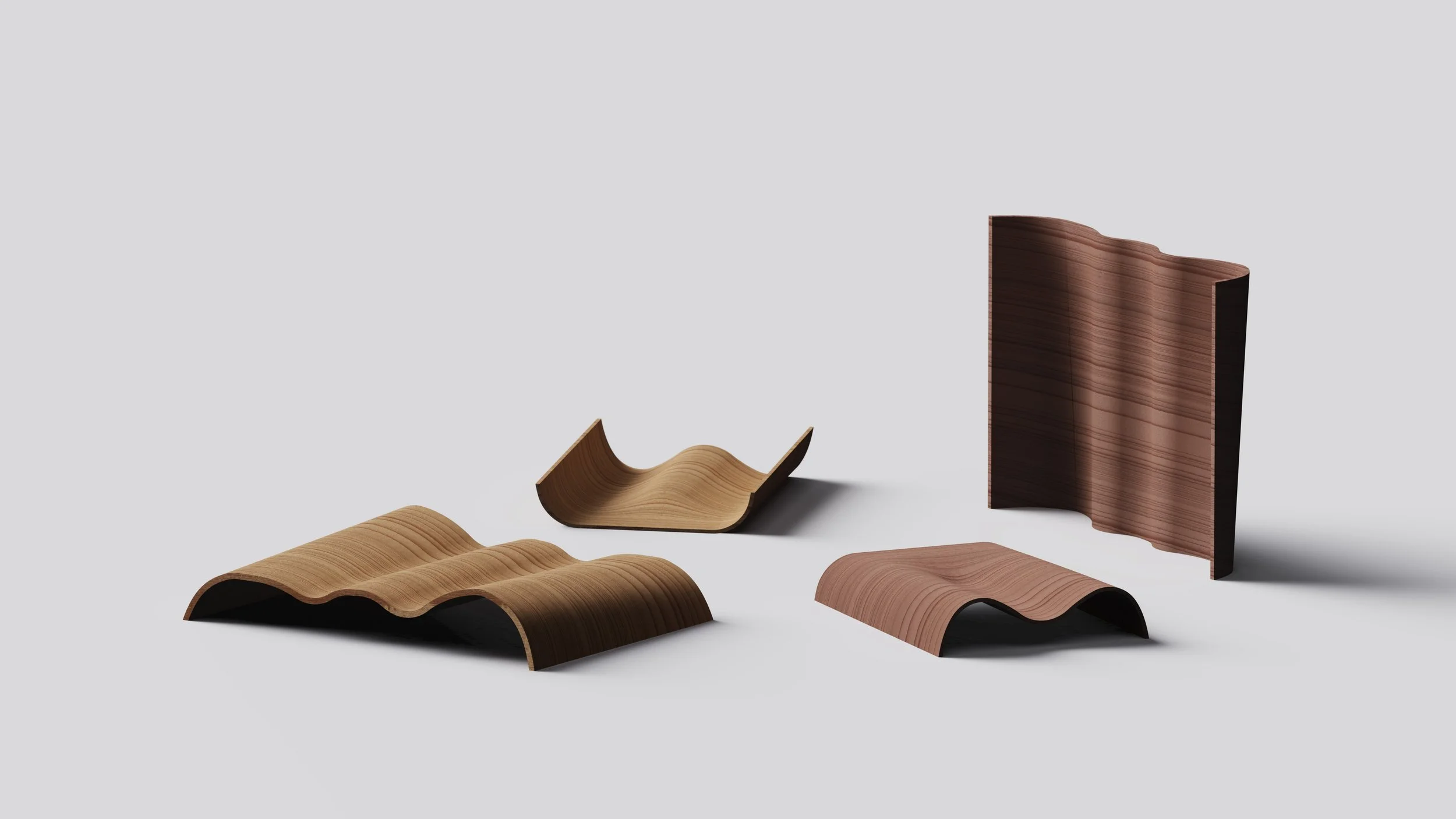

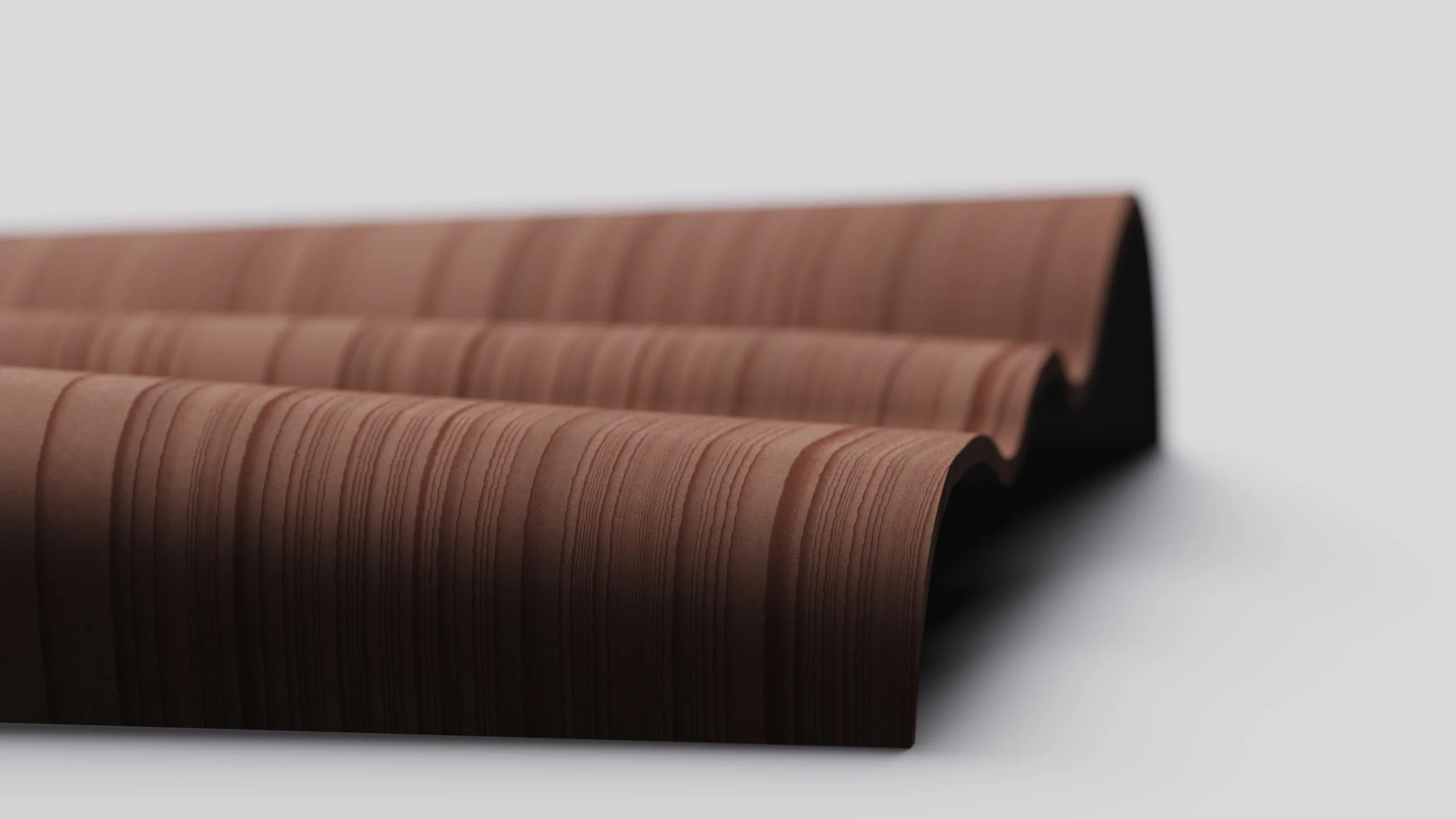

Lilian is a tabletop vessel designed to elegantly display wine bottles or cherished objects. Inspired by Scandinavian design, it emphasizes materiality and function. Crafted from wood, Lilian brings natural warmth, shaped with refined curves that invite both visual and tactile engagement.

-

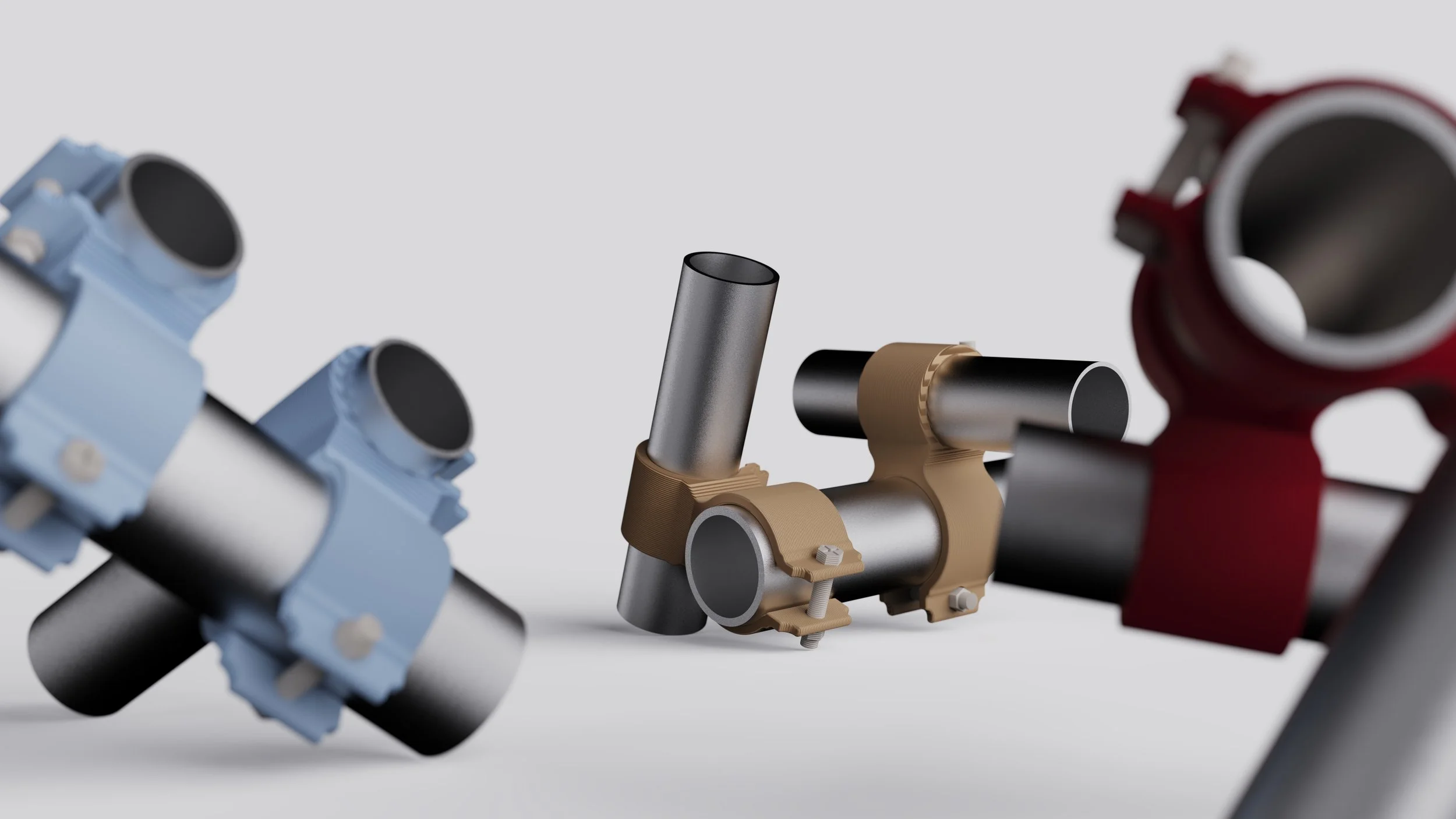

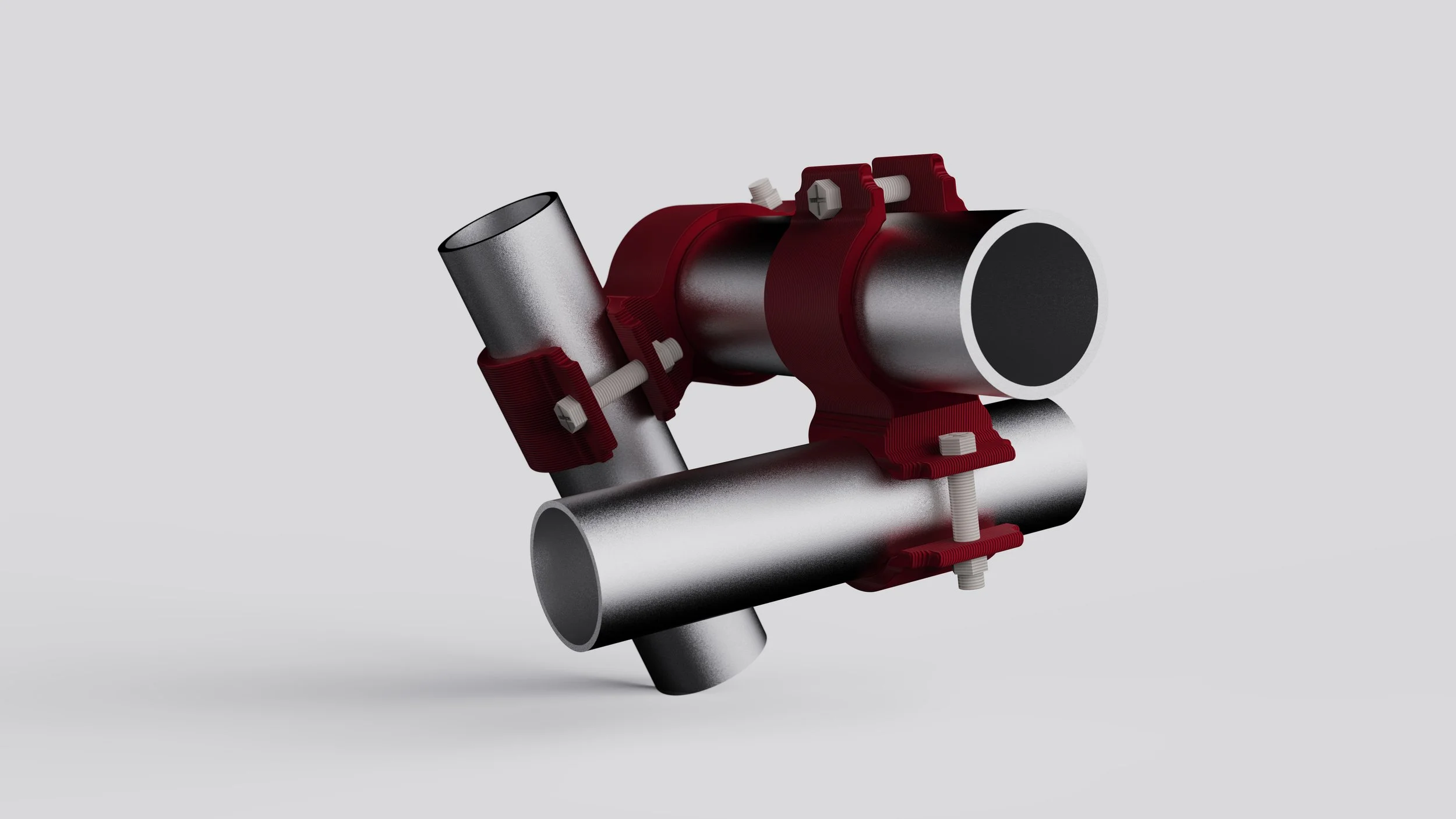

Knox is a scaffolding-inspired modular vessel designed as a distinctive accent piece. Its components can be assembled in various ways, offering a playful, customizable building experience. Knox was showcased in the NYCxDESIGN × Souvenir 2025 exhibition.

-

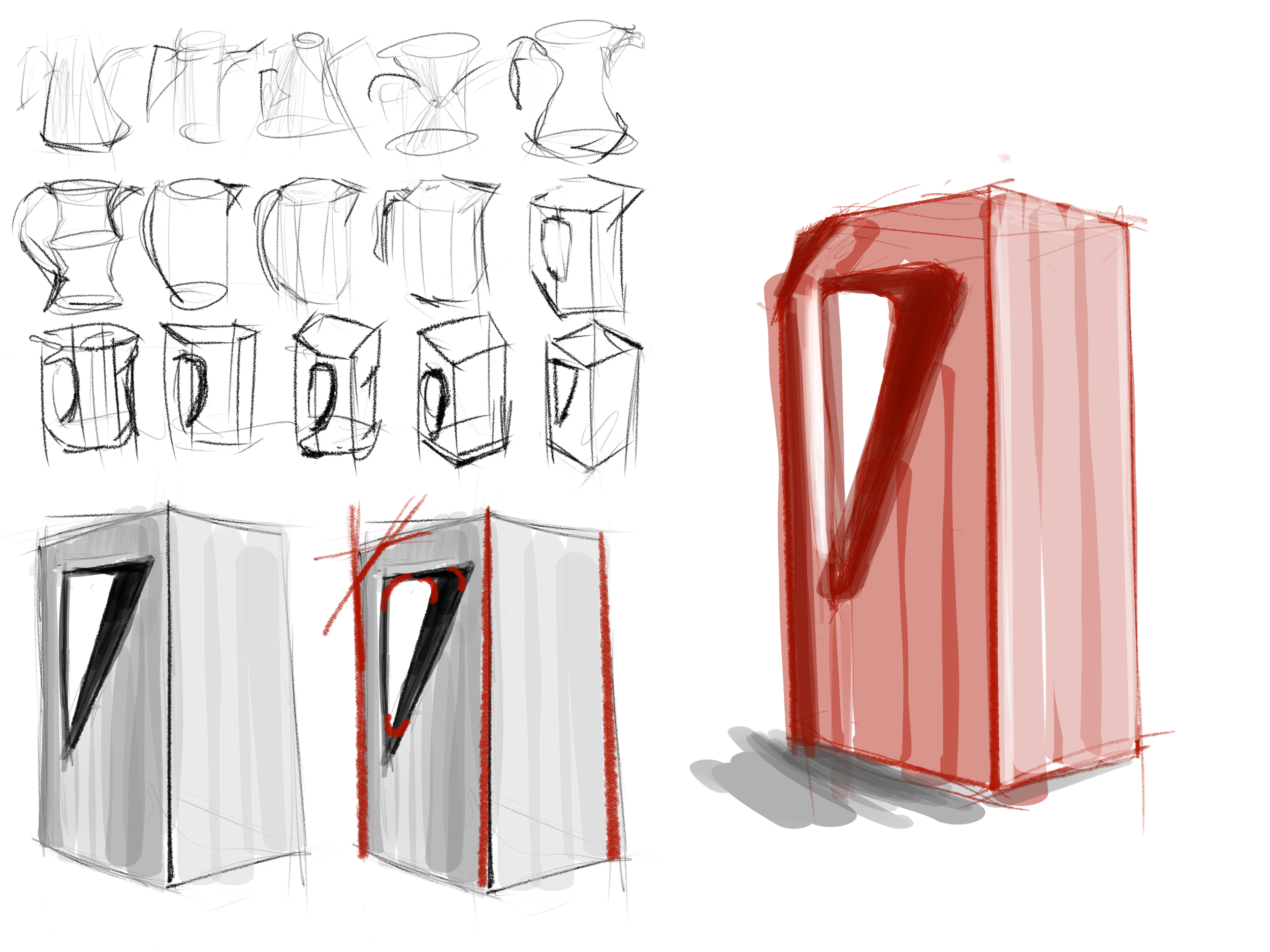

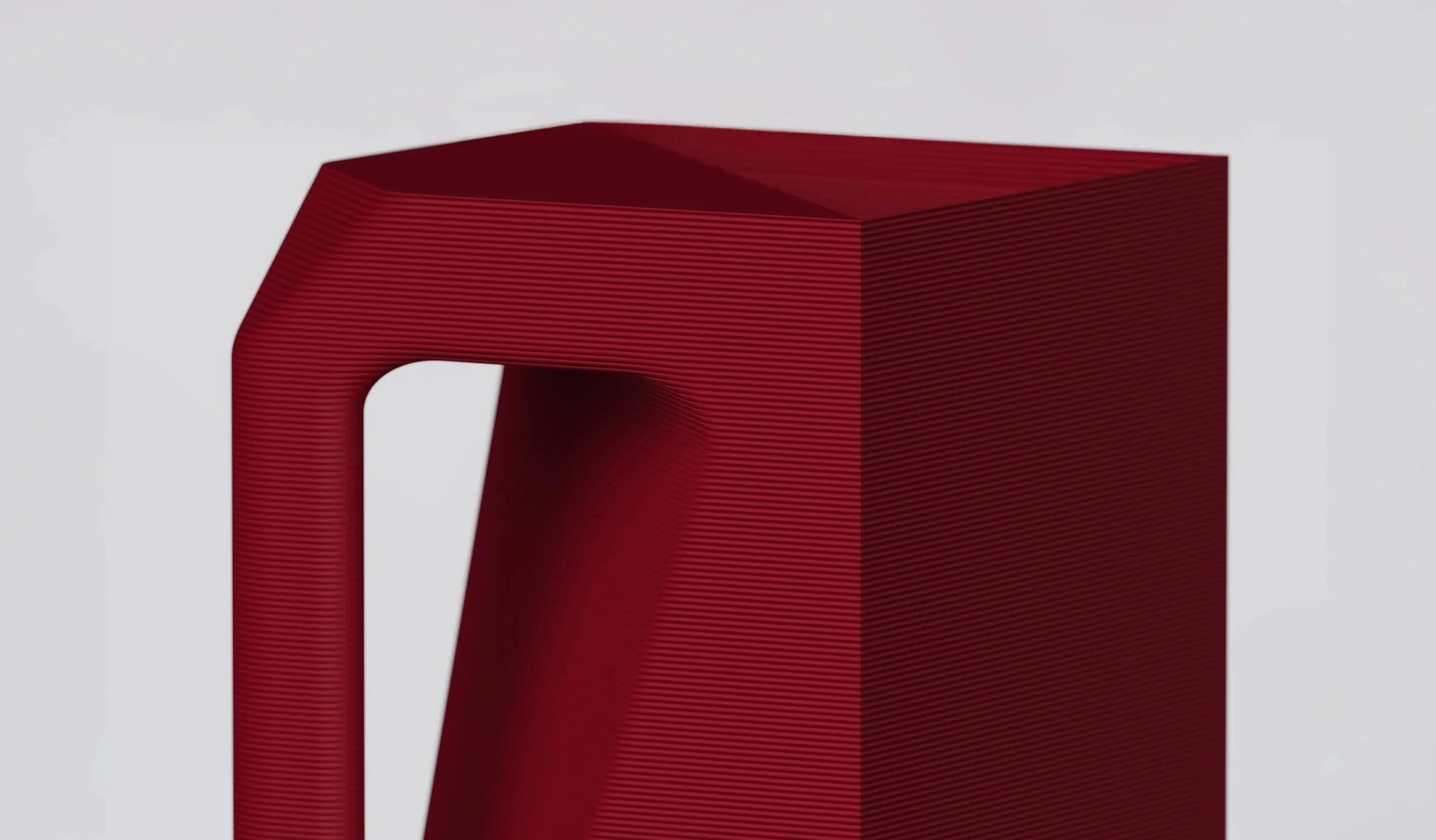

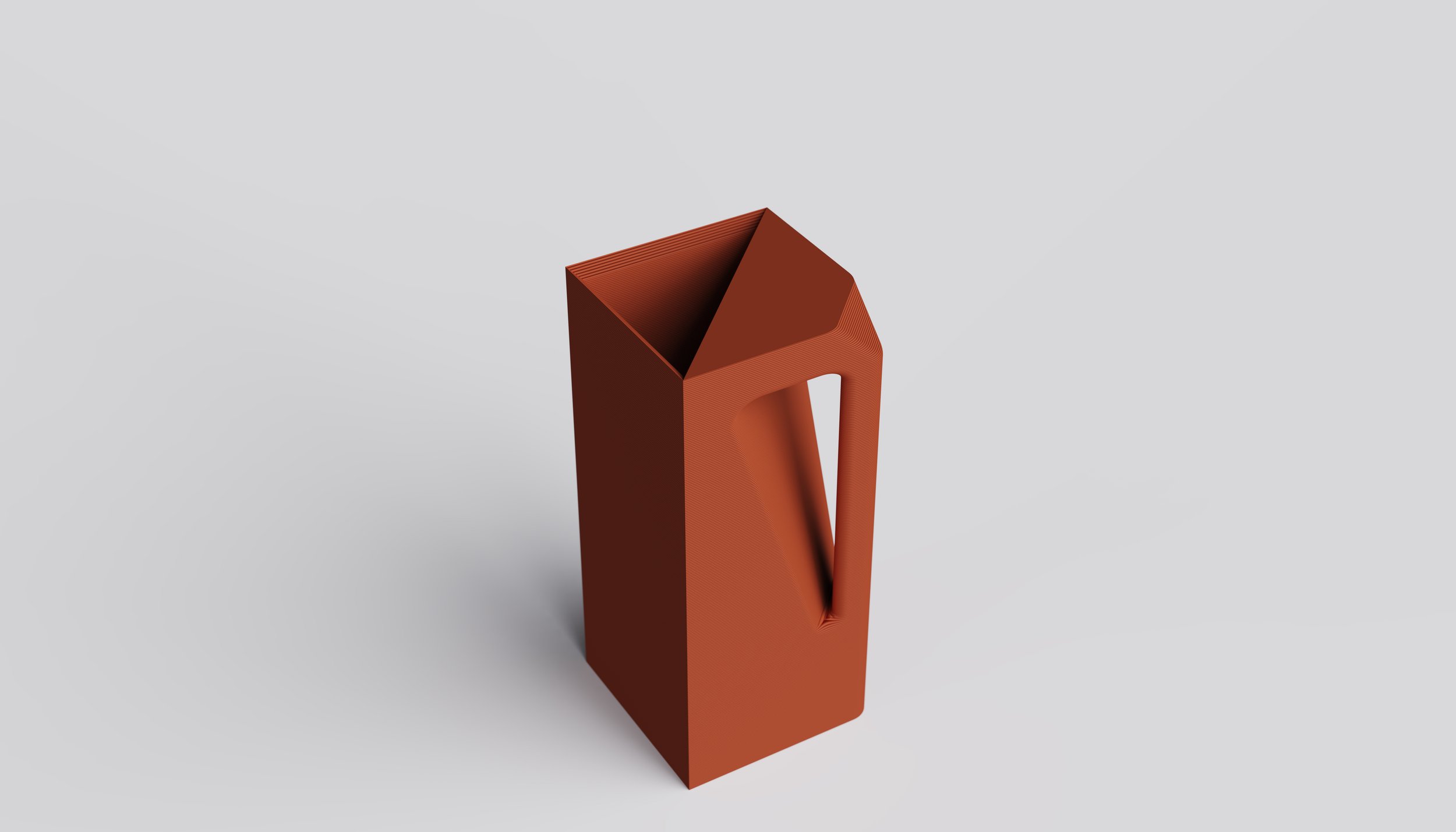

Henry is a PLA-printed watering kettle designed to blend seamlessly into a range of environments. Unlike the typical watering can, Henry is more vibrant, with a form defined by clear, intentional lines. Its design brings character and refinement to an everyday tool, making it both functional and expressive.